M公制螺纹_全钨钢挤压,无沟丝攻(牙攻)

M1.0*0.25-RH4-2P ,M6*1.0-RH8-2P

设计制作满足自动化生产的高效能/高寿命/高精度等高经济价值的钨钢直沟丝攻必须针对被加工件以下的参数特征制作最适用的螺纹丝攻,

1.螺纹直径&牙距 2.工件材质 3.通孔/盲孔 4.螺纹深度 5.品管检验要求

|

客户需求确认单-范例 Order List-Example |

||||||||

|

序号 |

总类 |

螺纹规格-精度 |

被削材质 |

通孔/盲孔 |

螺纹深度 |

检验要求 |

设备导程 |

特殊要求 |

|

1 |

全钨钢 |

M10x1.5-6H |

青铜 |

盲孔 |

15mm |

通止规合格 |

稳定 |

牙规+塞规检验合格 |

|

2 |

焊接 |

3/4-16UNF-2B |

压铸铝 |

通孔 |

20mm |

工作实配 |

不稳定 |

不稳定 |

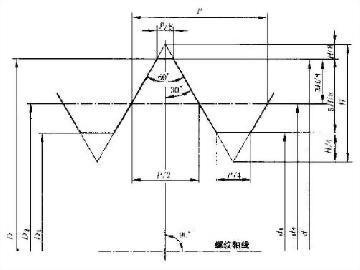

本公司备有公制 M 螺纹 统一UN螺纹 惠氏W螺纹 管用螺纹 G PT PF PS NPSM NH NPT NPSL NPSF等各国螺纹标准规范,满足用户不同螺纹制造组合装配之设计需求。

本公司生产多种丝攻标准柄,包含 JIS柄 DIN 柄 铣刀柄 ER筒夹柄 等多种丝攻柄选择,可满足不同设备之使用需求。

M公制螺纹_全钨钢挤压,无沟丝攻(牙攻)

M1.0*0.25-RH4-2P ,M6*1.0-RH8-2P

|

全鎢鋼無屑絲攻-公制螺紋 & 統一細螺紋-JIS方頭圓柄 |

|||||||||

|

Solid Carbide Taps -Roll Form (Fluteless)-Metric Thread (JIS Shank) |

|||||||||

|

公制螺紋 M/MF |

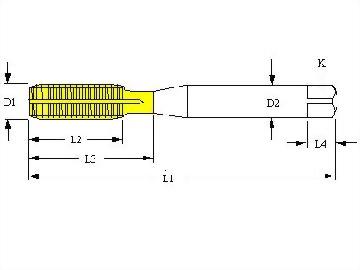

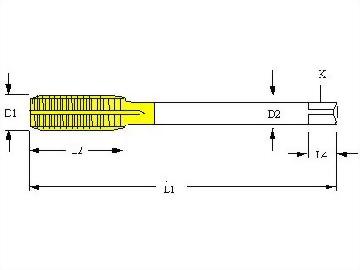

形 狀 Shape |

四方柄 Square |

精 度 |

無效牙長 |

備 註 |

||||

|

總長(L) |

刃長(Lc) |

工作長(Lw) |

柄徑(d) |

對邊(k) |

邊長(Lk) |

倒 角 |

|||

|

M1.4*0.3 |

50 |

6 |

|

3 |

2.5 |

5 |

6H |

2P/4P |

|

|

M1.6*0.35 |

50 |

6 |

|

3 |

2.5 |

5 |

6H |

2P/4P |

|

|

M1.8*0.35 |

50 |

6 |

|

3 |

2.5 |

5 |

6H |

2P/4P |

|

|

M2*0.4 |

50 |

6 |

|

3 |

2.5 |

5 |

6H |

2P/4P |

|

|

M2.5*0.45 |

50 |

6 |

|

3 |

2.5 |

5 |

6H |

2P/4P |

|

|

M3*0.5 |

50 |

6 |

|

4 |

3.2 |

6 |

6H |

2P/4P |

|

|

M3.5*0.6 |

50 |

6 |

|

4 |

3.2 |

6 |

6H |

2P/4P |

|

|

M4*0.7 |

50 |

6 |

|

5 |

4 |

7 |

6H |

2P/4P |

|

|

M5*0.8 |

60 |

7 |

|

5.5 |

4.5 |

7 |

6H |

2P/4P |

|

|

M6*1.0 |

60 |

8 |

|

6 |

4.5 |

7 |

6H |

2P/4P |

|

|

M8*1.25 |

70 |

10 |

|

6.2 |

5 |

8 |

6H |

2P/4P |

|

|

M10*1.5 |

75 |

12 |

|

7 |

5.5 |

8 |

6H |

2P/4P |

|

|

M12*1.75 |

75 |

14 |

|

8.5 |

6.5 |

9 |

6H |

2P/4P |

|

|

MF4*0.5 |

50 |

8 |

|

5 |

4 |

7 |

6H |

2P/4P |

|

|

MF5*0.5 |

60 |

8 |

|

5.5 |

4.5 |

7 |

6H |

2P/4P |

|

|

MF6*0.5 |

60 |

8 |

|

6 |

4.5 |

7 |

6H |

2P/4P |

|

|

MF6*0.75 |

60 |

8 |

|

6 |

4.5 |

7 |

6H |

2P/4P |

|

|

MF8*0.75 |

70 |

8 |

|

6.2 |

5 |

8 |

6H |

2P/4P |

|

|

MF8*1.0 |

70 |

10 |

|

6.2 |

5 |

8 |

6H |

2P/4P |

|

|

MF10*0.75 |

75 |

8 |

|

7 |

5.5 |

8 |

6H |

2P/4P |

|

|

MF10*1.0 |

75 |

10 |

|

7 |

5.5 |

8 |

6H |

2P/4P |

|

|

MF10*1.25 |

75 |

12 |

|

7 |

5.5 |

8 |

6H |

2P/4P |

|

|

MF12*1.0 |

75 |

12 |

|

8.5 |

6.5 |

9 |

6H |

2P/4P |

|

|

MF12*1.25 |

75 |

12 |

|

8.5 |

6.5 |

9 |

6H |

2P/4P |

|

|

MF12*1.5 |

75 |

12 |

|

8.5 |

6.5 |

9 |

6H |

2P/4P |

|